IDE III Cutting Head

No other head in the market like the IDE!

Dead on alignment = less downtime, longer focusing tube life, faster cutting speed, better edge quality and lower garnet usage!

Click Here to read the full letter from Ian Harry

SO MUCH DEPENDS ON THE QUALITY OF THE WATER STREAM...

If you were to ask ... What would be the single most important thing that you could do to maximise cutting speed, quality of cut, and the overall efficiency of your cutting operations?

If you were to ask ... What would be the single most important thing that you could do to maximise cutting speed, quality of cut, and the overall efficiency of your cutting operations?

Take a close look at the quality of the stream of water coming from your focusing tube!

Most likely you may find it difficult to actually see whether the quality is good or otherwise... however this is the critical factor that governs the whole efficiency of your system!!

Performance Waterjet has installed IDE cutting heads on all makes of waterjet machine for over 10 years. We guarantee that the IDE cutting head will save your business money from day one.

Satisfaction Guaranteed... Or Your Money Back!

If after installing and using the IDE cutting head for 2 weeks you aren't delighted with your waterjet's improved performance, the cutting head can be returned for a FULL REFUND.

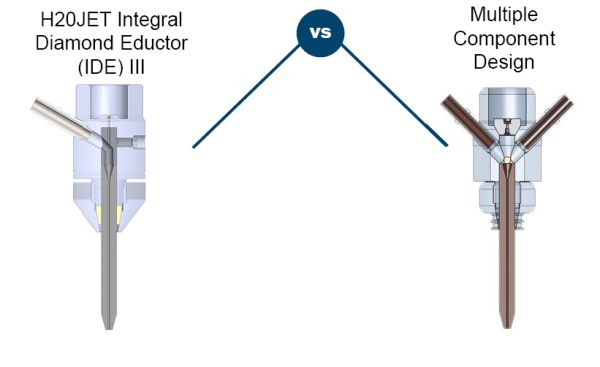

The H20JET Integral Diamond Eductor (IDE) consistently demonstrates superior performance and reduced cost when compared with other styles of cutting heads. Every IDE III Cutting Head has a factory aligned diamond orifice which is precisely focussed so that the water stream fires right down the centre of the focusing tube.

Dead on alignment of the water stream ensures maximum energy is delivered to the workpiece and results in a faster cutting speed with less garnet per linear metre of cut.

Here's why:

- Cutting Speed: Water stream deflection off the inside of the focusing tube causes loss of cutting energy.

- Edge Quality: Deflection of the water stream off the inside of the focusing tube also interrupts the laminar flow of the water stream and causes a ragged edge on your cut. For a smooth, consistent edge you must have a sharp, coherent stream of water.

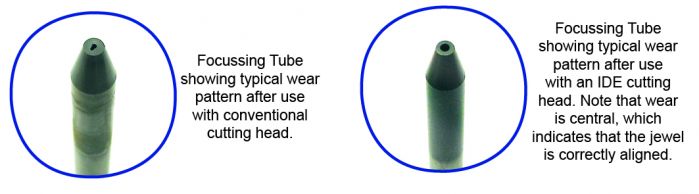

- Focusing Tube Life: Misalignment of the water jet also causes premature wear on the inside of the focusing tube... and increases your operating costs.

Focussing Tube Wear:

What Others Say...

“It cuts better, faster and more accurately; delivers a better edge finish and is also maintenance and trouble free!” - Dardi Operator, Gold Coast

“Our tips are lasting longer, the edge is sharper and we are definitely cutting quicker!” - Waterjet Operator, Canberra

In response to upgrading to a H20 IDE III cutting head assembly and Feedline precision, a waterjet operator said: "We are extremely happy with the speed of cutting and the improvement of edge quality. We are cutting 3mm PVC sheet at 4000mm per minute, which we have never ever done before – and we could cut it quicker but the software won’t let us!! I’ve cut more in the last two months than I have the first ten months...Now we don’t have to use any manual labour, we can’t keep the work up to the machine." - Metal Fabricator, Tasmania

"It cuts twice as fast as our old head... [the cut is] half the thickness and we are no longer sandblasting the surface around the cut." - Metal Fabricator, Victoria

"Since the changeover, it has been such an improvement with cutting finish, cutting speed, minimal down time and reduced usage of garnet. We reckon it’s great!" - Metal Fabricator, Melbourne

Buyer's Guide

For all the information you need on our range of machines, pumps and software